Metallurgical Image Analysis software, free download Windows 10

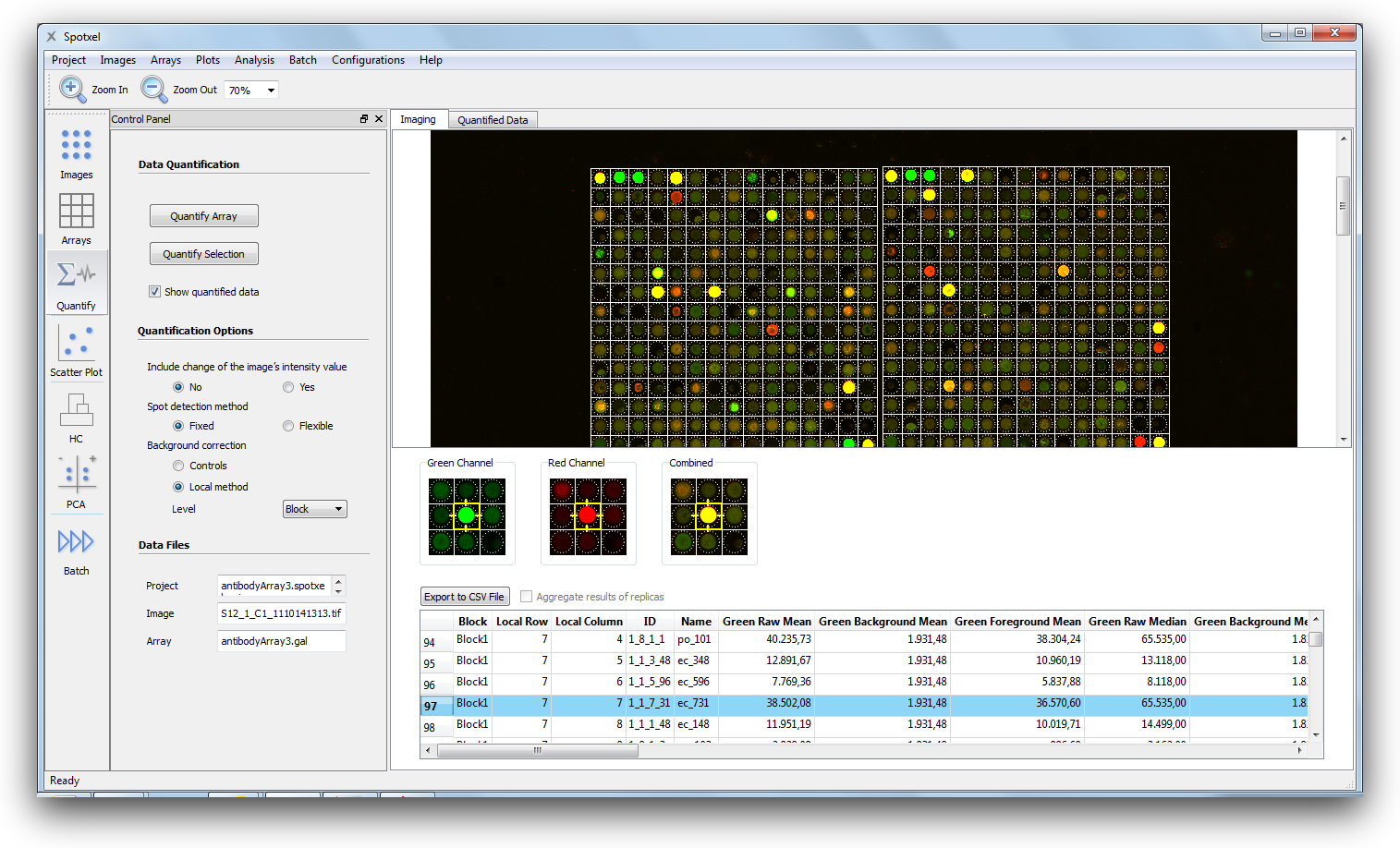

Reduce storage costs through disk space analysis & management.Disk space analyzer (Disk usage analysis software) is a free software utility for the visualization of disk space usage by getting the size for each folder (including subfolders) & files. In general, any standard format image may be viewed directly from a calibrated microscope or be imported into OmniMet for analysis. OmniMet software is offered at different levels of flexibility, functionality, and analytical power to meet the metrology needs of every laboratory requiring image data archiving and quantitative image analysis. Image Analysis & Micro-Measurement Software Introduction: Ver. 4.0 is A new generation Image analysis Software meant for Metallurgist to do analysis in the simplest way. This is a single screen window based system. The System is flexible, independent to adopt any capture card, camera and Microscope. Metallurgical microscopes for specimen testing and analysis. Buehler’s metallurgical microscopes and image analysis software for laboratories, research & development, and quality control departments.

Metallurgical Analysis Laboratory

| Brand | Metlab |

| Software Version | 2.5 |

| Is It Portable | Portable |

| Usage/Application | Laboratory |

| Measurement | Length, Area, Angle, Diameter, Radius |

| Supporting OS | Window 7 |

| Communication Language | English |

Weld Check software is a powerful easy-to-use tool that enhances your ability to quickly and efficiently handle your most critical welding measurement and documentation software needs. Your workflow and productivity are greatly improved. Weld Check has been designed with your welding cross-section measurement needs in mind. Weld Check is measurement module allows you to quickly measure such items as your fillet welds, throat, leg lengths and penetration.

Use Weld Check Measurement Tolerance indicator to improve performance by having the software automatically tell you if a measurement is out of the tolerance range.

The following report concerns the analysis of a fillet weld, a weld of approximately triangular cross section joining two surfaces at approximately right angles to each other. Important measurements made by the distance from the root if the fillet to the center of the face (or throat), the distance from the root of the joint to the junction between the exposed surface of the weld and the base metal (or leg), the angles and the root penetration.Measurements that could have been done with the same ease or similar sample are among others : depth of HAZ (heat affected zone), area of HAZ, joint penetration, phase counting, etc

The measurement remain unaffected if the image is zoomed for better accuracy. T he magnifier tool is also available which can be switched on any part of image. The tool zooms only the region surrounding the cursor allowing to increase the drawing precision while still seeing the whole sample.

Image analysis system can measure a sequence of specific characteristics or welded parts. The system brings the good tool with the good color when it the time for the operator to use it.

Metallurgical Analysis Lab

View Complete Details